Lonovae Advances Sustainable Logistics with Innovative Sleeve Pack Containers in China

JIANGYIN, JIANGSU, CHINA, November 7, 2025 /EINPresswire.com/ -- Jiangyin Lonovae Technology Co., Ltd., a leading supplier of Returnable Transport Packaging (RTP), is introducing new innovations in reusable packaging to address the growing need for sustainable and efficient logistics solutions. The company’s sleeve pack containers are designed to improve material handling and reduce waste across global supply chains, aligning with the industry’s increasing focus on environmental responsibility and operational efficiency.

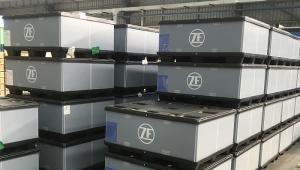

Founded in 2015, Lonovae has developed a strong position in the RTP sector by focusing on high-performance packaging systems made from advanced polymer materials. Its primary product, the collapsible sleeve pack container, combines structural strength, lightweight design, and reusability, making it suitable for use in industries such as automotive, electronics, and manufacturing. These containers are engineered to help businesses reduce packaging waste and transportation costs while maintaining the protection required for high-value goods.

The Role of Returnable Transport Packaging (RTP) in Modern Supply Chains

As global supply chains become more complex, many organizations are moving toward reusable packaging models that support sustainability and cost efficiency. Returnable Transport Packaging (RTP) allows containers and materials to be reused multiple times, reducing single-use packaging waste and helping companies meet their sustainability targets.

At the center of Lonovae’s RTP solutions is the sleeve pack container — a collapsible, three-part system consisting of a pallet, sleeve, and lid made from high-strength polypropylene (PP) honeycomb panels. This construction offers advantages such as durability, impact resistance, and reduced weight. When not in use, the containers can be folded flat, reducing storage space and return freight costs. The design also provides secure containment for sensitive or irregularly shaped components, which is especially beneficial for long-distance and international transport.

Market Developments and Industry Outlook

The RTP market continues to grow, supported by broader shifts toward circular economies, environmentally conscious regulations, and automation in logistics operations. Many sectors — including automotive, electronics, and pharmaceuticals — are increasing their reliance on reusable systems to enhance efficiency and reduce material waste.

Market research indicates steady growth for reusable packaging systems globally, reflecting a clear movement toward long-term cost savings and lower environmental impact. As supply chains become increasingly digital and data-driven, demand is also rising for packaging solutions that integrate with automated and intelligent logistics systems.

Lonovae’s approach reflects these trends. Through continuous development in polymer materials and its proprietary use of PP Honeycomb Panels, the company aims to improve container strength and longevity while maintaining lightweight efficiency. Its ongoing exploration of smart packaging technologies, including potential integration with IoT-based tracking systems, aligns with future trends in automated logistics and data-driven supply chain management.

Quality and Standards Compliance

Lonovae’s product development and manufacturing processes adhere to internationally recognized standards to ensure quality and reliability. The company’s operations follow strict procedures for material selection, production consistency, and testing to maintain the durability and reusability of each container.

Its adherence to industry and environmental standards supports clients in meeting their own compliance requirements across domestic and international supply chains. The focus on process control, product traceability, and lifecycle analysis also reflects growing customer expectations for transparency and sustainability in packaging systems.

Core Advantages of Lonovae’s RTP Solutions

Lonovae’s position in the RTP sector is supported by several key strengths that distinguish its product portfolio:

Advanced Material Engineering: The use of PP honeycomb panels provides a combination of strength, low weight, and moisture resistance, improving performance under demanding transport conditions.

Collapsible Efficiency: Containers can be folded to reduce volume by up to 80% when empty, lowering return shipping costs and warehouse space requirements.

Durability and Service Life: Designed for repeated use, Lonovae’s containers withstand high turnover cycles and varying environmental conditions, extending product lifespan.

Manufacturing Consistency: The company maintains quality through standardized production methods and compatibility with existing material-handling systems, supporting automation and international logistics.

Product Range Diversity: Beyond sleeve pack containers, Lonovae produces a range of collapsible crates and bulk containers suitable for different industry needs.

Applications Across Industries

Lonovae’s RTP solutions are used in multiple industrial contexts:

Automotive Manufacturing: For the secure transport of large or irregularly shaped components, reducing damage during movement between suppliers and assembly lines.

Electronics and High-Tech: Providing protective, anti-contamination packaging for precision components such as sensors and circuit boards.

General Manufacturing and Retail Logistics: Supporting the efficient movement of raw materials and finished goods, as well as reusable crates for retail distribution and storage.

These applications demonstrate how reusable packaging systems can contribute to cost reduction and waste minimization across diverse sectors. According to customer reports, the adoption of Lonovae’s RTP products has led to measurable improvements in handling efficiency and reductions in single-use packaging materials.

A Focus on Sustainable Growth

Lonovae’s continued development reflects its commitment to advancing sustainable logistics and responsible manufacturing. By emphasizing durability, reusability, and environmental performance, the company supports its customers’ efforts to build cleaner, more efficient supply chains.

As industries move toward greener and smarter logistics systems, Lonovae plans to expand its global presence while investing further in material innovation and design optimization. The company’s long-term objective is to contribute to a more sustainable logistics ecosystem, where reusability and circular design principles are the standard practice.

For additional information about Lonovae’s Returnable Transport Packaging solutions, please visit:

https://www.lonovae.com/

Founded in 2015, Lonovae has developed a strong position in the RTP sector by focusing on high-performance packaging systems made from advanced polymer materials. Its primary product, the collapsible sleeve pack container, combines structural strength, lightweight design, and reusability, making it suitable for use in industries such as automotive, electronics, and manufacturing. These containers are engineered to help businesses reduce packaging waste and transportation costs while maintaining the protection required for high-value goods.

The Role of Returnable Transport Packaging (RTP) in Modern Supply Chains

As global supply chains become more complex, many organizations are moving toward reusable packaging models that support sustainability and cost efficiency. Returnable Transport Packaging (RTP) allows containers and materials to be reused multiple times, reducing single-use packaging waste and helping companies meet their sustainability targets.

At the center of Lonovae’s RTP solutions is the sleeve pack container — a collapsible, three-part system consisting of a pallet, sleeve, and lid made from high-strength polypropylene (PP) honeycomb panels. This construction offers advantages such as durability, impact resistance, and reduced weight. When not in use, the containers can be folded flat, reducing storage space and return freight costs. The design also provides secure containment for sensitive or irregularly shaped components, which is especially beneficial for long-distance and international transport.

Market Developments and Industry Outlook

The RTP market continues to grow, supported by broader shifts toward circular economies, environmentally conscious regulations, and automation in logistics operations. Many sectors — including automotive, electronics, and pharmaceuticals — are increasing their reliance on reusable systems to enhance efficiency and reduce material waste.

Market research indicates steady growth for reusable packaging systems globally, reflecting a clear movement toward long-term cost savings and lower environmental impact. As supply chains become increasingly digital and data-driven, demand is also rising for packaging solutions that integrate with automated and intelligent logistics systems.

Lonovae’s approach reflects these trends. Through continuous development in polymer materials and its proprietary use of PP Honeycomb Panels, the company aims to improve container strength and longevity while maintaining lightweight efficiency. Its ongoing exploration of smart packaging technologies, including potential integration with IoT-based tracking systems, aligns with future trends in automated logistics and data-driven supply chain management.

Quality and Standards Compliance

Lonovae’s product development and manufacturing processes adhere to internationally recognized standards to ensure quality and reliability. The company’s operations follow strict procedures for material selection, production consistency, and testing to maintain the durability and reusability of each container.

Its adherence to industry and environmental standards supports clients in meeting their own compliance requirements across domestic and international supply chains. The focus on process control, product traceability, and lifecycle analysis also reflects growing customer expectations for transparency and sustainability in packaging systems.

Core Advantages of Lonovae’s RTP Solutions

Lonovae’s position in the RTP sector is supported by several key strengths that distinguish its product portfolio:

Advanced Material Engineering: The use of PP honeycomb panels provides a combination of strength, low weight, and moisture resistance, improving performance under demanding transport conditions.

Collapsible Efficiency: Containers can be folded to reduce volume by up to 80% when empty, lowering return shipping costs and warehouse space requirements.

Durability and Service Life: Designed for repeated use, Lonovae’s containers withstand high turnover cycles and varying environmental conditions, extending product lifespan.

Manufacturing Consistency: The company maintains quality through standardized production methods and compatibility with existing material-handling systems, supporting automation and international logistics.

Product Range Diversity: Beyond sleeve pack containers, Lonovae produces a range of collapsible crates and bulk containers suitable for different industry needs.

Applications Across Industries

Lonovae’s RTP solutions are used in multiple industrial contexts:

Automotive Manufacturing: For the secure transport of large or irregularly shaped components, reducing damage during movement between suppliers and assembly lines.

Electronics and High-Tech: Providing protective, anti-contamination packaging for precision components such as sensors and circuit boards.

General Manufacturing and Retail Logistics: Supporting the efficient movement of raw materials and finished goods, as well as reusable crates for retail distribution and storage.

These applications demonstrate how reusable packaging systems can contribute to cost reduction and waste minimization across diverse sectors. According to customer reports, the adoption of Lonovae’s RTP products has led to measurable improvements in handling efficiency and reductions in single-use packaging materials.

A Focus on Sustainable Growth

Lonovae’s continued development reflects its commitment to advancing sustainable logistics and responsible manufacturing. By emphasizing durability, reusability, and environmental performance, the company supports its customers’ efforts to build cleaner, more efficient supply chains.

As industries move toward greener and smarter logistics systems, Lonovae plans to expand its global presence while investing further in material innovation and design optimization. The company’s long-term objective is to contribute to a more sustainable logistics ecosystem, where reusability and circular design principles are the standard practice.

For additional information about Lonovae’s Returnable Transport Packaging solutions, please visit:

https://www.lonovae.com/

Jiangyin Lonovae Tenology Co., Ltd.,

Jiangyin Lonovae Tenology Co., Ltd.,

+86 186 6101 0305

sophia@lonovae.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.